For decades, steel barriers have been the go-to solution for industrial safety. From warehouses to manufacturing plants, they have been installed with the expectation that their strength and durability will provide the best protection against collisions. But times have changed, and so has safety technology.

The question is: Are steel barriers still the best choice for modern industrial environments? The answer is no—and here’s why.

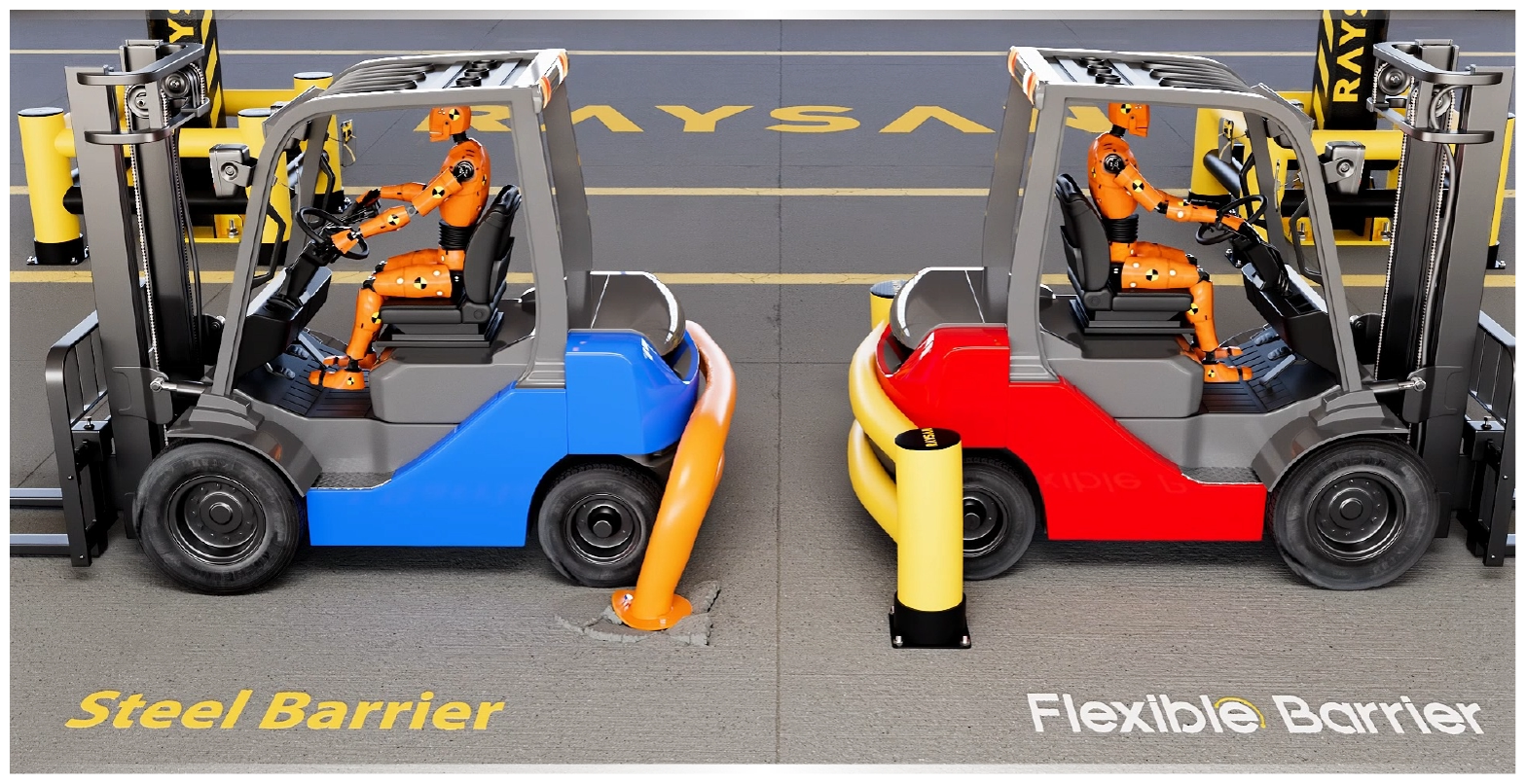

Steel is strong, but it’s also rigid. When a forklift or vehicle collides with a steel barrier, the impact energy is not absorbed—it’s transferred. This results in severe damage not just to the vehicle but also to the floor and even the barrier itself. In many cases, a single accident can lead to high repair costs and potential safety risks.

On the other hand, polymer barriers absorb and distribute impact energy rather than transferring it. This reduces damage to vehicles, floors, and the barrier system itself—saving businesses from unnecessary maintenance expenses.

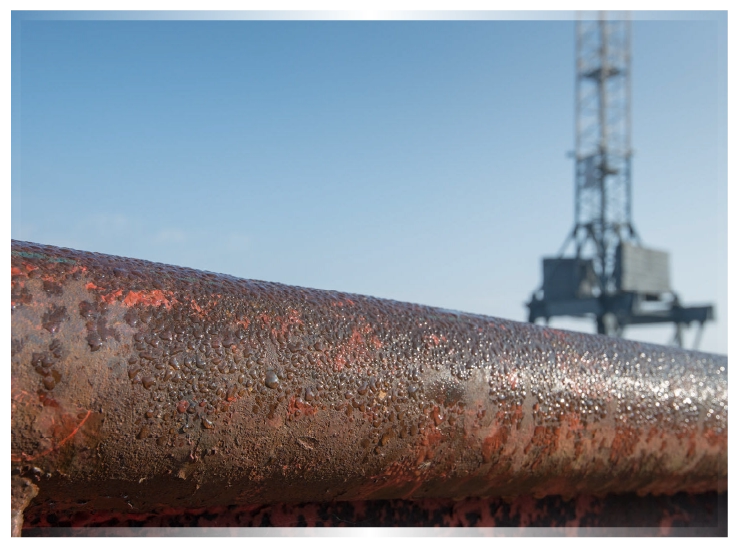

Industrial environments are tough. Exposure to moisture, chemicals, and constant wear and tear can cause steel barriers to corrode, weaken, and ultimately fail over time. Regular maintenance, repainting, and even full replacements are often necessary to keep them functional.

Polymer barriers, in contrast, are corrosion-resistant and maintenance-free. They are designed to withstand harsh conditions, making them a more durable and cost-effective solution in the long run.

Steel barriers require heavy-duty installation, often involving drilling into the floor, welding, and additional labor. If a barrier gets damaged, replacing it is a hassle—removing and reinstalling steel is both time-consuming and expensive.

With polymer barriers, installation is faster and easier, and replacements are straightforward. Their modular designs allow for simple adjustments, making them an ideal choice for businesses that value flexibility and efficiency.

The purpose of safety barriers is to protect not just infrastructure but also workers. Unfortunately, steel barriers can be a hazard to employees. When collisions occur, the shock can travel through the barrier, creating additional risks.

Polymer barriers, with their flexibility and impact absorption, significantly reduce the risks of secondary injuries and create a safer work environment overall.

Modern industrial safety requires modern solutions. While steel barriers have served their purpose in the past, the industry has evolved, and so should the safety measures within it. Polymer barriers are the next-generation solution, providing enhanced protection, cost savings, and long-term reliability.